Ipleyiti yeCarbon Steel

Ipleyiti yentsimbi yekhabhoni

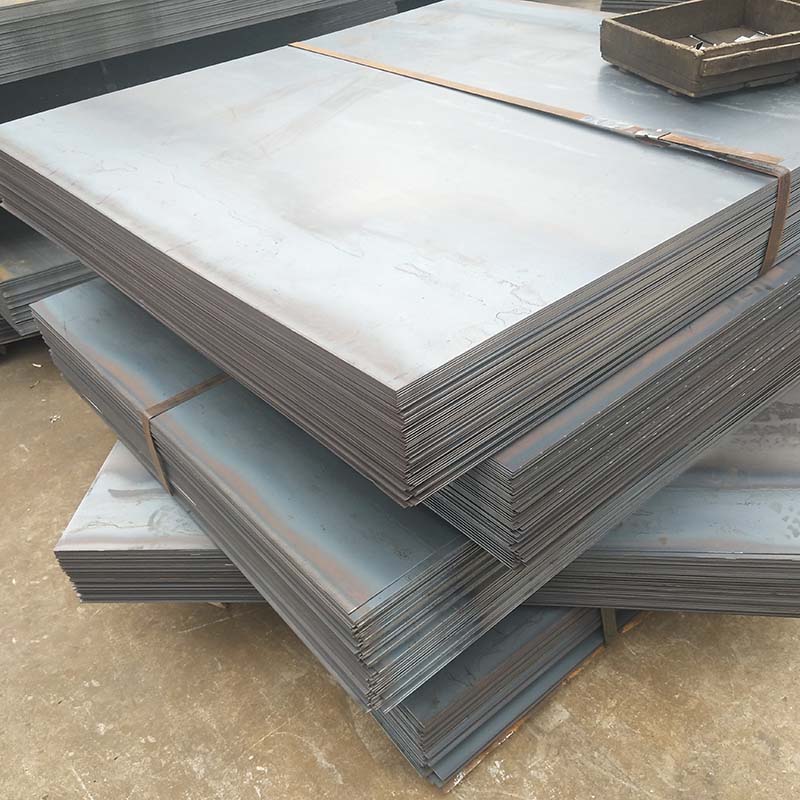

Ipleyiti yethu yeCarbon Steel yenziwe ngobuchule ukuze ihlangabezane nemigangatho yomgangatho ongqongqo, iqinisekisa ukusebenza okuthembekileyo kunye nokuqina okuhlala ixesha elide.Ingaba ufuna isiseko esomeleleyo soomatshini abanzima, imathiriyeli eyomeleleyo yeeprojekthi zokwakha, okanye icandelo elithembekileyo lezixhobo zoshishino, ipleyiti yethu ye-carbon steel sisisombululo esifanelekileyo.

Ngokuxhathisa kwayo okuphezulu kwi-corrosion, i-abrasion, kunye nefuthe, ipleyiti yethu ye-carbon steel yenziwe ukuba imelane neyona meko inzima yokusingqongileyo, iyenze ilungele ukusetyenziswa ngaphandle nangaphakathi.Amandla ayo aphezulu kunye nokwakheka okugqwesileyo kuvumela ukwenziwa lula kunye nokubumba, ukulungiselela iimfuno ezithile zeeprojekthi zakho.

Ukuguquguquka kwepleyiti yethu yentsimbi yekhabhoni kuyenza ibe yi-asethi yexabiso kuwo onke amashishini ahlukeneyo, kubandakanya ulwakhiwo, ukuvelisa, iimoto, nokunye.I-weldability yayo ekhethekileyo kunye nokusebenza kwayo kuphucula ngakumbi ukusebenziseka kwayo, ibonelela ngokuguquguquka kuyilo kunye neenkqubo zokuhlanganisa.

H Uluhlu lobungakanani beBeam

| Igqitywe tu | Ukutyeba (MM) | Ububanzi (MM) | ||

| Kubanda kwaqengqeleka | 0.8~3 | 1250, 1500 | ||

| Ishushu esongwayo | 1.8~6 | 1250 | ||

| 3-20 | 1500 | |||

| 6-18 | 1800 | |||

| 18-300 | 2000,2200,2400,2500 | |||

Iinkcukacha zeMveliso

Kutheni Khetha Thina

Sinikezela ngeemveliso zentsimbi kwiminyaka eyi-10, kwaye sinothungelwano lwethu olucwangcisiweyo lokubonelela.

* Sinestokhwe esikhulu esinobukhulu obuphangaleleyo kunye namabanga, izicelo zakho ezahlukeneyo zinokulungelelaniswa ngenqanawa enye ngokukhawuleza okukhulu kwiintsuku ezili-10.

* Amava atyebileyo okuthumela ngaphandle, iqela lethu eliqhelene namaxwebhu okukhutshwa, ubuchwephesha emva kwenkonzo yokuthengisa iya kwanelisa ukhetho lwakho.

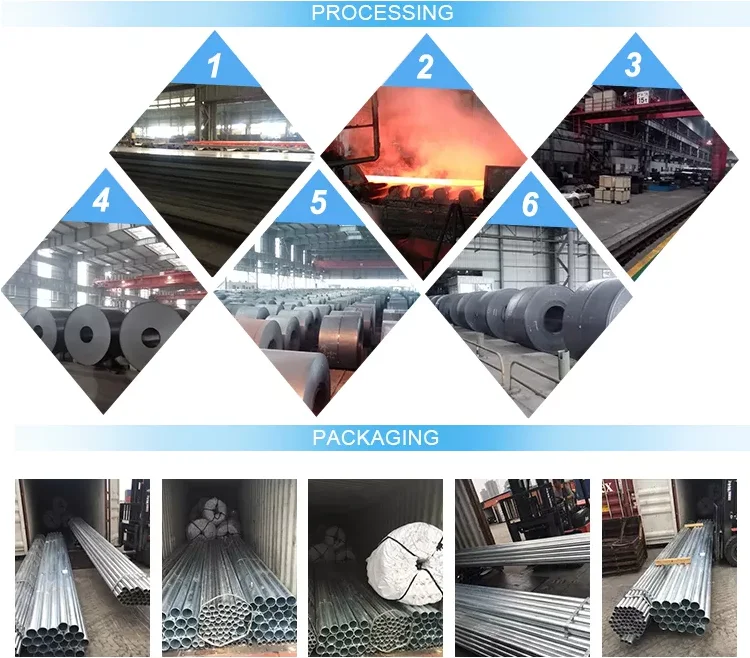

Ukuhamba kweMveliso

Isatifikethi

Ingxelo yoMthengi

FAQ

Intsimbi yentsimbi yentsimbi luhlobo lwentsimbi efakwe kwi-zinc ukuze ikhusele ukubola.Le nkqubo, eyaziwa ngokuba yi-galvanization, ibandakanya ukuntywiliselwa kwentsimbi kwindawo yokuhlambela ye-zinc etyhidiweyo, eyenza umaleko okhuselayo kumphezulu wentsimbi.Oku kugquma kunceda ukuthintela umhlwa kunye nokubola, ukwenza intsimbi yentsimbi ibe yintsimbi ethandwayo kwizicelo zangaphandle nakwimizi-mveliso.Ukugquma kwe-zinc kwakhona kunika umqobo onceda ukwandisa ixesha lokuphila kwentsimbi, okwenza kube yinto ehlala ixesha elide kunye neendleko ezifanelekileyo kwiiprojekthi zokwakha kunye nokuvelisa.

- Intsimbi yentsimbi yentsimbi isetyenziswa ngokuqhelekileyo kuluhlu olubanzi lwezicelo, kubandakanywa ukwakhiwa, ukuveliswa kweemoto, kunye nezixhobo zoshishino.Izakhiwo zayo ezikwaziyo ukumelana nomhlwa ziyenza ifaneleke kakuhle kwizakhiwo zangaphandle ezinje ngocingo, iintsimbi zokugada, kunye nezinto zokufulela.Kwishishini leemoto, intsimbi yepleyiti enezibilini isetyenziselwa ukwenza imizimba yemoto, amacandelo e-chassis, kunye nezinye iindawo ezifuna ukumelana neemeko ezirhabaxa zokusingqongileyo.Ukongeza, ihlala isetyenziswa kwimveliso yoomatshini boshishino, iitanki zokugcina, kunye nezixhobo zolimo ngenxa yokuqina kwayo kunye nokuchasana nokubola.