Mild steel checkered plate

MILD STEEL CHECKERED PLATE

H Beam Size List

|

Thickness (MM) |

Width (MM) |

Thickness (MM) |

Width (MM) |

|

2 |

1250, 1500 |

6 |

1250, 1500 |

|

2.25 |

6.25 |

||

|

2.5 |

6.5 |

||

|

2.75 |

6.75 |

||

|

3 |

7 |

||

|

3.25 |

7.25 |

||

|

3.5 |

7.5 |

||

|

3.75 |

7.75 |

||

|

4 |

8 |

||

|

4.25 |

8.25 |

||

|

4.5 |

8.5 |

||

|

4.75 |

8.75 |

||

|

5 |

9 |

||

|

5.25 |

9.25 |

||

|

5.5 |

9.5 |

||

|

5.75 |

9.75 |

||

|

10 |

12 |

Product Details

Why Choose Us

We supply steel products over 10 years, and we have our own systematic supply chain.

* We have a large stock with widly size and grades, your various requests could be coordinated in one shipment very fast within 10days .

* Rich export experience,our team familiar with documents for clearance, professional after sale service will satisfied your choice.

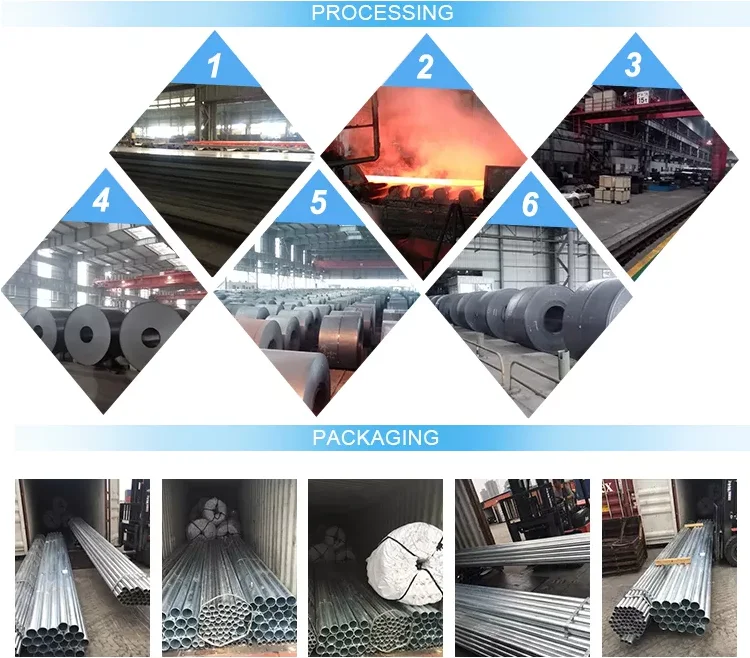

Production Flow

Certificate

Customer Feedback

FAQ

Checkered steel plate refers to a steel plate with patterns on the surface, which is called a Checkered plate, and its patterns are in the shape of a combination of flat beans, diamonds, round beans, and flat circles. Generally used for anti slip flooring and staircase boards, etc. In some places, patterned boards have many advantages such as beautiful appearance, anti slip ability, enhanced performance, and steel saving. It is widely used in fields such as transportation, construction, decoration, equipment surrounding bottom plates, machinery, shipbuilding, etc. Generally speaking, the user does not have high requirements for the mechanical and mechanical properties of the patterned board, so the quality of the patterned board is mainly reflected in the pattern formation rate, pattern height, and pattern height difference. The commonly used thicknesses on the market range from 2.0-8mm, and there are two common widths: 1250 and 1500mm.

- Round bean shaped checkered steel plate, marked as: Round bean shaped checkered steel plate Q235-A-4 * 1000 * 4000-GB/T3277-91

- Diamond patterned steel plate, marked as B3-4 * 1000 * 4000-GB3277-82

- The surface of the patterned steel plate shall not have bubbles, scars, cracks, folds, or inclusions, and the steel plate shall not have layering.

- The surface quality is divided into two levels:

- Normal precision: The surface of the steel plate allows for thin layers of oxide scale, rust, surface roughness caused by the detachment of oxide scale, and other local defects with height or depth exceeding the allowable deviation. It is allowed to have inconspicuous burrs and individual marks with a height not exceeding the grain height on the pattern. The maximum area of a single defect shall not exceed the square of the grain length.

- High precision: The surface of the steel plate allows for a thin layer of oxide scale, rust, and other local defects with a height or depth not exceeding half of the thickness tolerance. The pattern is intact and undamaged, and slight burrs with a height not exceeding half of the thickness tolerance are allowed on the pattern.