Galvanized Sheet Coil

GALVANIZED STEEL COIL

Our galvanized steel coil undergoes a meticulous galvanization process, which involves coating the steel with a layer of zinc to protect it from rust and corrosion. This process not only enhances the durability of the steel but also gives it a visually appealing finish, making it suitable for both functional and aesthetic purposes.

One of the key advantages of our galvanized steel coil is its versatility. It can be easily formed, welded, and manipulated to suit specific project requirements, making it a popular choice for fabricating a wide range of products such as roofing materials, gutters, ductwork, and automotive parts. Its ability to withstand harsh environmental conditions and extreme temperatures makes it an excellent choice for outdoor and industrial applications.

In addition to its exceptional durability and versatility, our galvanized steel coil is also highly cost-effective. Its long lifespan and low maintenance requirements make it a smart investment for businesses looking to reduce long-term operational costs and minimize the need for frequent replacements.

Galvanized Steel Coil Size List

|

Stock Galvanized Steel Coil size list |

||

|

Thickness (MM) |

Width (MM) |

Length (MM) |

|

0.8 to 3.0 |

1250/ 1500 |

Customized |

Product Details

Why Choose Us

We supply steel products over 10 years, and we have our own systematic supply chain.

* We have a large stock with widly size and grades, your various requests could be coordinated in one shipment very fast within 10days .

* Rich export experience,our team familiar with documents for clearance, professional after sale service will satisfied your choice.

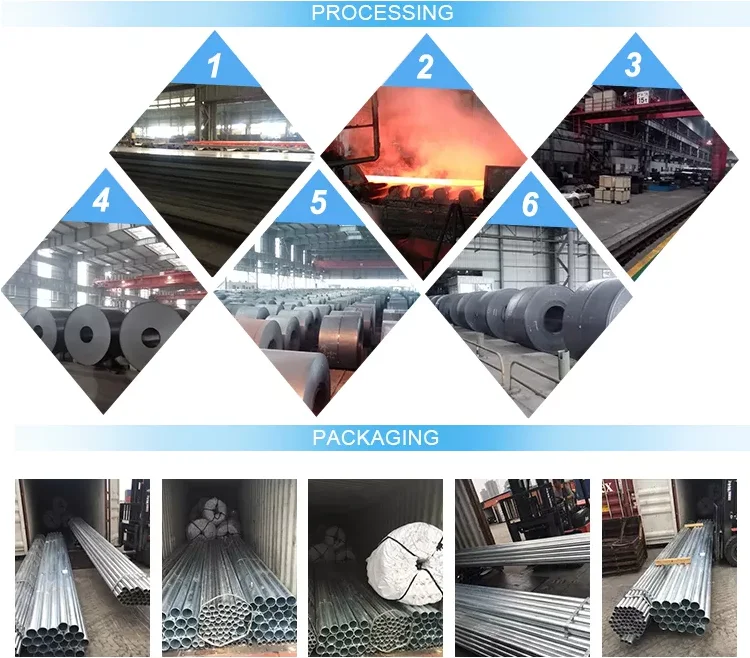

Production Flow

Certificate

Customer Feedback

FAQ

Galvanized steel coils are widely used in various industries due to their corrosion-resistant properties. Some common uses of galvanized steel coils include:

- Construction: Galvanized steel coils are used in the construction industry for making roofing, siding, and structural components. The corrosion resistance of galvanized steel makes it suitable for outdoor applications where exposure to moisture and harsh weather conditions is a concern.

- Automotive: Galvanized steel coils are used in the automotive industry for manufacturing parts and components that require corrosion protection. These coils are used in the production of car bodies, chassis, and other structural elements.

- Manufacturing: Galvanized steel coils find applications in various manufacturing processes, such as the production of appliances, HVAC systems, and industrial equipment. The corrosion resistance and durability of galvanized steel make it a preferred material for these applications.

Overall, the uses of galvanized steel coils are diverse and encompass a wide range of industries where corrosion resistance and durability are essential.

Galvanized steel coils offer several benefits that make them a popular choice in various industries. Some of the key benefits of using galvanized steel coils include:

- Corrosion resistance: Galvanized steel coils are coated with a layer of zinc, which provides excellent protection against corrosion. This makes them suitable for outdoor and harsh environmental conditions.

- Durability: The zinc coating on galvanized steel coils enhances their durability, making them resistant to damage and wear. This results in a longer lifespan and reduced maintenance requirements.

- Cost-effectiveness: Galvanized steel coils are cost-effective due to their long lifespan and low maintenance requirements. They offer a high level of protection against corrosion at a relatively low cost.

- Versatility: Galvanized steel coils can be used in a wide range of applications across different industries, thanks to their versatility and adaptability to various manufacturing processes.

Overall, the benefits of using galvanized steel coils make them a preferred choice for applications where corrosion resistance, durability, and cost-effectiveness are important factors.